Many a wire fence contractors, wholesalers or importers have had to face sudden increase in shipping fees, variations in tariffs, unexpected quality inconsistencies or just a change in wire mesh fence supplier’s personnel. These are part of the daily challenges any wire mesh fence importer has to deal with. With time and the appropriate skills, steel fence companies learn to efficiently deal with the day-to-day challenges of importing.

At the beginning of purchasing, there was the checklist

But what about newcomers? What if your local steel fence business needs to leverage global sourcing to live on and grow? Dealing with fluctuations in raw material prices, currency exchanges, and pressure on wire mesh fence supply stock level does not come naturally for everyone. This guide comes in handy for welded wire mesh specialists and steel wire fence buyers who seek to improve the efficiency and reliability of their wire mesh imports.

Use a welded wire fence supplier sourcing checklist

“At the beginning of purchasing, there was the checklist” illustrates well how important preparation and planning is to purchasing. It is utterly essential to those young wire fence purchasers and untrained wire mesh buyers.

The checklist will list your company requirements in terms of product, delivery, payment and help you consolidate your data when comparing welded wire fence quotations, and suppliers. The fence sourcing checklist needs to include the following:

When auditing a supplier, make sure you check if they currently have the very same product you are looking for. Selecting a wire mesh supplier specialized in welded mesh panels when buying rolls does not really make sense.

Always consider the size of the supplier, and its welded mesh monthly output before you make your choice. Preferring a big factory over a medium-sized one because they talk big may work against you. With a factory that fits the size of your business, you get leverage.

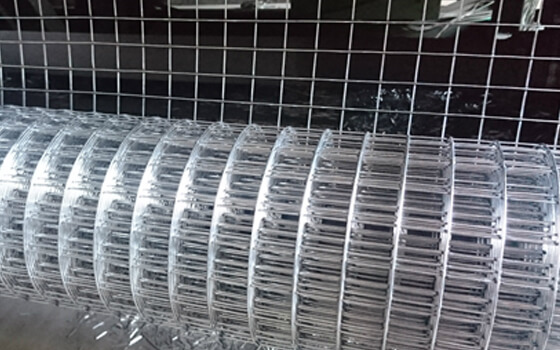

Wire mesh fences, whether they are welded or woven, are fairly inexpensive products. There is no need to increase costs because you chose a factory located far from ports and without any decent expressway network available.

When considering a welded wire mesh manufacturer, exercise care and assess their quality management. It should be as balanced as possible (good maintenance programme, efficient spot checks, applicable warranty). Any answer such as “don’t worry my friend, we have great record” should be considered a high risk for the buyer.

Keys to placing a profitable woven or welded wire mesh order

You have now completed the sourcing part, identified and screened out the best welded mesh suppliers for you. It is now time to place a wire mesh order with your manufacturer. This step requires attention to minute details and smart thinking in order to avoid unnecessary hassles.

Last Checks before placing your wire mesh order

Check thoroughly the Proforma Invoice that the supplier will provide you with. Any error, approximation, or unclear information can lead to misunderstanding, or even disputes. Delivery time is a sensitive issue, especially if you have yourself previously agreed to a delivery date with your own client. A fortnight is a great buffer time when your company has signed a delivery contract with a client whose wholesale welded wire mesh fence you get from a manufacturer in China.

When in doubt, take necessary measures to ensure that you get accurate data before you actually sign the order. Whether it is about welded wire fence coating quality, or welded mesh fabric specification, secure a sample and have it tested by a company with previous experience in wire mesh testing.

You are having difficulties with your wire mesh supply chain?

Seeking Help?

Things you need your Wire Mesh Supplier to fully understand before manufacturing

Always make sure that your supplier is aware of the following as soon as order placement :

You do not compromise with wire mesh quality

You plan to have your welded wire fence and accessories inspected before shipment by a quality inspection company.

Supplier will prefer to leave a few pallets unpacked for the inspector to take samples out.

Balance payment only happens when you’ve confirmed receipt of goods

You need to place a L/C at sight, it requires specific documents, which may take some time to obtain.

Some steel wire suppliers have no experience with L/C payment. In that case, turn towards another supplier. Also, L/C requires swift and accurate planning for your bank to receive the documents in time.

You don’t ship from China as long as the container is not full

You plan to ship their welded mesh rolls & posts with other building supplies. To fill the container allows you to make additional cost savings on your wire mesh imports. This technique is called “groupage” or a “FCL from China”.

Supplier will need to handle your goods and load them too in the container.

Make the most of your welded wire mesh shipping fees

2021 and 2022 have been very profitable years for shipping lines over the world. However, inflated shipping quotes have impacted on purchasing profitability, consumer prices increase and eventually spending index. To this day, shipping from China fees haven’t recovered their Today’s welded wire products importers need, more than ever, to make their shipments as profitable as possible.

The issue with wire fencing products, is that they :

- can not be squeezed into smaller packaging to save on volume in the shipping container;

- need specific protection to avoid damage during loading, transport & unloading;

Thus, most of the time, wire mesh buyers end up with shipping containers that are not fully loaded. Smart planners will come up with solutions to take as much space as possible, while untrained ones will have to pay for space wastage.

The obvious solution to waste of space in shipping containers is groupage, or multi-supplier order. That is, wire mesh buyers place their order of welded wire mesh with their usual manufacturer. And they also buy lighter, smaller products such as DIY products, Garden supplies, or Building Accessories that will fill most of the container.

In doing so, steel fence importers ventilate the shipping fee on a larger panel of products, thus lower the unit cost of a welded wire mesh panel, or welded wire mesh roll.