Wire mesh fencing is used in garden fences, commercial enclosures and industrial perimeter systems. It is one of the most widely used perimeter solutions across the globe. As of 2024, report says that the global wire mesh market was valued around USD5.9billion, with a projected growth expected to reach USD9.4 billion valuation in 2033.

Despite its widespread use, the basic design of wire mesh fences has not changed much over the years. Most products available today—whether welded or chain-link panels with galvanized or PVC coatings—are quite similar to those made decades ago. Aside from variations in mesh size, wire gauge, or coating type, the essential functionality and construction have remained consistent.

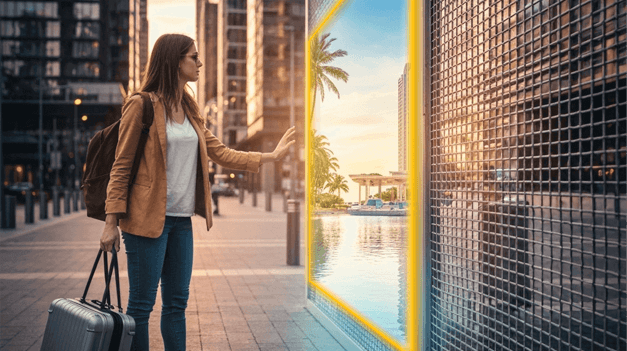

How then, can we keep the steel wire fencing industry alive and growing if the finished products do not evolve as fast as the IoT and AI revolution pushes us to? What will wire mesh fences be in a future where smart cities, mass surveillance advanced materials are the new norm? We have come up with a few ideas for hi-tech steel wire fences that range from solar-powered fence coatings to advanced mesh fabrics that merge with IoT systems, and sustainable fence options.

Limits of Modern Wire Mesh Fences

“The best way to predict the future is to create it”

–Alan Key

Wire mesh fences, whether qualified as “modern”, or “new” are in reality far from featuring any world shattering innovation. The reasons are simple, but we have decided to freshen your memory so here they are:

Mesh Fence Cost is the ultimate limit.

Steel wire fences feel very standard, because they are made for it. In the end, a wire mesh fence is, before all, a practical separation between two spaces. They are engineered to be strong and cost efficient. Just that. They just are very common and their market value is strong. The basic design and materials of these fences have not changed much for many, many years because there is no need to. Most improvements we see today are only small changes, not big innovations.

PVC Coatings on wire fence already exist since the 30’s

Many fences now use outdoor coatings like PVC, PE or other polymers. These coatings protect the wire against rust, and “dress” them with a color (usually green, grey, black, white or yellow). While coatings are great as a weather barrier, they unfortunately are a problem for our environment. Plastic decay leads to the release of chemicals as well as what we call “polymeric dust”. Polymeric dust gets everywhere, thanks to the wind. Today we can find it even in the most remote regions of the USA, China, France and many other countries.

Zinc Coating aka Galvanization

You may already know but the process of galvanization was patented in 1836 by a French civil engineer. In 1984, lead-free galvanizing was introduced as part of a new, more environmentally safe solution to protecting steel mesh from rust. Apart from this innovation, only very small variations in the molten zinc bath formula differentiate a finished mesh from another.

The spread of Anti-Climb Panels

Before the COVID pandemic, fences with special panels to stop people climbing over were mostly for high-security places like prisons or airports. But the post Covid world apparently wants more of these anti-climb mesh panels. Also, while the “double wire” panel was already on the market for decades, it was considered too pricey. Yet again, these once before “high-end” or “industry-specific” fencing solutions are finding new markets today, but without the need for product change.

Is Steel Wire Fencing never to evolve? We don’t think so.

Except for minor improvements in manufacturing, galvanizing and product placement, the wire mesh fencing industry builds upon stable, non-changing goods. Maybe the reason lies in the applications of mesh fences: as a perimeter solution, full stop. There is none to little incentive to implement great changes on existing products. But it is our opinion that even though there has not been big changes in the materials used, what the fence can actually do, or how people experience it since the late 1900s, there is still potential for innovations for steel wire fencing in 2025.

Potential Future Fencing Mesh Wire Products

Solar-Integrated Wire Mesh

Coating wire mesh with photovoltaic materials or UV-sensitive paint would allow fences to transform the suns’ energy into electrical power. New steel wire fences would be similar to micro-power generators that could trigger an automatic watering system, or signage. This aligns with growing corporate sustainability goals and residential energy independence needs. Fences could generate DC electricity passively – turning perimeter barriers into electricity making devices, without the need to buy new land! Such a nice energy cost offsets for property owners.

Noise-Reducing Acoustic Mesh

Transforming something so common as a fence into a sound barrier is not a fiction. With today’s deadening coatings and noise cancelling systems, somewhere in the world, a company could come up with a solution that does not need to be a 40mm sound-dampening wall made of mesh fence. Unlike current solid noise barriers, this approach maintains airflow while reducing traffic/industrial sounds. The value proposition: effective noise control without the visual bulk or installation complexity of “sandwich panel” solutions, appealing to urban developers and homeowners near busy areas.

Temperature-Responsive Color Mesh

Using thermo-chromic coatings (such as this one) would enable fences to change colors as temperature increase or decrease. We believe that it would have 2 positive impacts :

- Visually engaging end users and giving them of sense of temperature changes, warn them about the right outfit to wear, and triggering an interest on nature’s cycles.

- Create a unique experience for end users, and people in public spaces with color changing fences. A great compromise between security and decorative fencing markets.

Integrated Glow Technology (EL Wire Mesh)

Covering mesh fence with glowing paints (such as this one) would bring a more mixed experience to end users. Instead of sensing dark mesh fabric, they could be looking at vertical artistic patterns painted on the inner side of their fence.

Warnings could be painted directly on fences where needed, and reduce the need for additional, freestanding warning signage.

Commercial and public spaces could be customized to fit the seasonal holiday without incurring additional material, complex logistics. A team of painters with specific directions would turn a mesh fence into a Christmas’ light fresco for example.

Touch-Sensing Security Mesh

Incorporating capacitive or piezoelectric sensors directly into wire strands could transform passive barriers into active security systems. Practical applications include:

- Instant intrusion alerts upon climbing attempts

- Contact-based automated gate access

- Tamper detection during cutting attacks

This creates upgrade opportunities for security-focused segments while integrating smoothly with existing access systems.

Wrap up

These mesh wire fence concepts represent practical evolutions rather than distant fantasies. Each leverages established materials science while addressing clear market demands: energy efficiency, noise mitigation, visual communication, safety enhancement, and smarter security. For fencing supplies distributors and buyers, such innovations could open new product categories with added value and higher margins, plus a huge potential for brand differentiation. The core takeaway: wire mesh fencing is ready for its first mass technological innovation in decades.